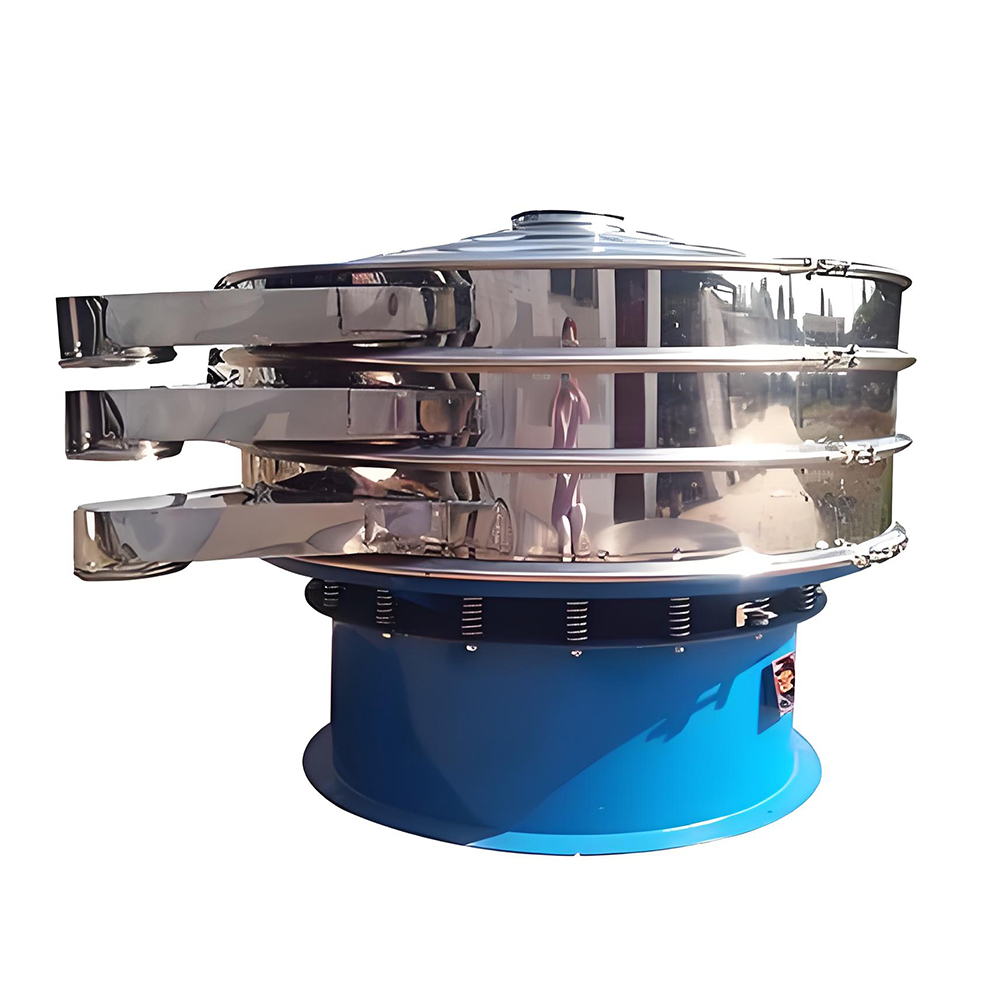

Product Details

The rotary vibrating screen is a high-precision fine powder screening machine with low noise and high efficiency. It can quickly change the screen in 3-5 minutes. It has a fully enclosed structure and is suitable for screening and filtering particles, powders, mucus and other materials. The rotary vibrating screen uses a vertical motor as the excitation source. Eccentric weights are installed at the upper and lower ends of the motor to convert the rotational motion of the motor into horizontal, vertical, and tilted three-dimensional motion, and then transfer this motion to the screen surface. By adjusting the phase angle of the upper and lower ends, the movement trajectory of the material on the screen surface can be changed.

1. Small size, light weight, easy to move, the direction of the discharge port can be adjusted arbitrarily, coarse and fine materials are automatically discharged, and can be operated automatically or manually. 2. The screening accuracy is high and the efficiency is high, and any powder, granule, or mucus can be used. 3. The screen is not clogged, the powder does not fly, the screening can reach 500 mesh (28 microns), and the filtration can reach 5 microns. 4. Unique mesh design (mother-child type), the screen can be used for a long time, the screen is easy to change, it only takes 3-5 minutes, it is simple to operate and easy to clean. 5. No mechanical action, simple maintenance, can be used in single or multiple layers, and the parts in contact with materials are all made of stainless steel (except for medical use).

Rotary vibrating screen is suitable for various screening needs such as particle size classification, powder screening, liquid filtration, etc. It is especially suitable for processing powdery, mucus and other materials, and can efficiently remove impurities and foreign matter. -chemical industry. In the chemical industry, rotary vibrating screens are widely used to screen chemical raw materials such as resins, coatings, and industrial drugs, as well as in processes such as crystallization, grinding, and filtration. -food industry. The food industry has high requirements for product quality and hygiene. The rotary vibrating screen is suitable for screening flour, sugar, salt, milk powder and other food raw materials. ——Pharmaceutical industry. The pharmaceutical industry has strict requirements for product quality and safety. The rotary vibrating screen can efficiently screen pharmaceutical raw materials such as traditional Chinese medicine powders and Western medicine powders, while meeting GMP standards. -mining. The mining industry needs to screen raw materials such as mineral powder and ore, and rotary vibrating screens can efficiently complete these screening tasks. -other industry. Rotary vibrating screens are also widely used in electric power, steel, paper and other industries as well as garbage treatment and wastewater recycling.